Wind Turbine Blade Repair

At BladeTex, we understand the critical role that wind turbine blades play in the overall performance of wind turbine system. Our comprehensive wind turbine blade repair services are designed to address and rectify a range of damages, ensuring your turbines operate at their peak efficiency. This page outlines our expertise in blade repairs, focusing on types we offer and the advanced techniques we employ.

Understanding Blade Repairs

Wind turbine blades are engineered for strength and durability, using composite materials that offer an optimal balance between weight and resilience. However, these components can still suffer from wear and tear or damage due to environmental conditions, operational stresses, and unforeseen incidents. Blade repairs are specialized procedures that restore the integrity and functionality of the blade by removing the damage and replacing the damage with the exact same fiberglass material and resin type.

Blade Repair Steps

*Each damage is unique and the below method is the basic outline of repairing*

1.Remove Damage

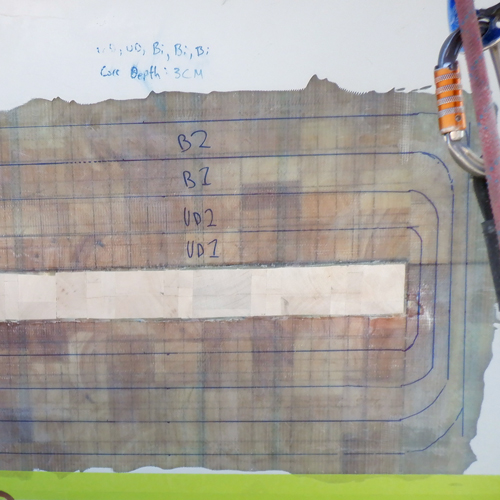

2.Determine Ply Information

3.Taper/Chamfer

4.Replace Removed Material (Laminate, Core)

5.Gel coat & Paint Finish

Types of Blade Repairs

We offer a comprehensive suite of wind turbine blade repair services that cover category 1-5 damages. Our skilled blade technicians are adept at diagnosing issues and implementing the most effective repair solutions. The types of composite repairs we specialize in include:

Core Replacement

Dry Fiberglass Repairs

Crack Repairs.

Laminate Replacement

Sandwich Repairs

Split Trailing Edge Repairs

Advanced Repair Techniques

To achieve the best results in composite repairs, BladeTex employs state-of-the-art techniques that ensure durability, efficiency, and reliability. Our two primary methods include:

Vacuum Bag Composite Repairs: This advanced technique involves placing the repaired area under a vacuum seal. The process ensures that the resin fully impregnates the fiberglass, eliminating air pockets and voids for a dense, strong repair. Vacuum bagging enhances the bond strength.

Hand Layup Composite Repairs: For certain types of damages, the hand layup method offers speed and effectiveness. This technique involves manually laying down layers of fiberglass and resin over the damaged area

Why Choose BladeTex for Composite Repairs?

Expertise and Experience

Our team of blade technicians brings together years of experience in the wind turbine blade repair industry. We are equipped with the knowledge and skills to address a wide range of damages, ensuring your rotor blades are in capable hands.

Sustainable Practices

As a company deeply committed to the wind energy sector, we employ sustainable practices in all our operations. Our repair processes are designed to extend the life of your blades, reducing the need for replacements, and minimizing waste.

Quality and Reliability

At BladeTex, we use only the highest grade materials and adhere to stringent ISO standards in all our repair processes. Our commitment to excellence means you can trust us to deliver wind turbine blade repairs that last.

Customized Solutions

We understand that each wind turbine and blade is unique. Our approach to composite repairs is highly personalized, ensuring that we meet the specific needs and challenges of your wind turbine.

.

Maximized Efficiency

By restoring your wind turbine blades to their optimal condition, we help maximize their efficiency and output. Our repairs are designed not only to fix damages but also to keep the blades’ aerodynamic performance.

Contact